New Strategy Doubling Liquid Fuel Production via Biomass

Prof. FU Yao’s Group from the Key Laboratory of Biomass Clean Energy of Anhui Province put forward a new strategy on biomass transformation which doubles the traditional liquid fuel production. The research released on the ‘Nature- Scientific Reports’(Sci. Rep. 2013, 3, 1244)under the title ‘Linked strategy for the production of fuels via formose reaction’.

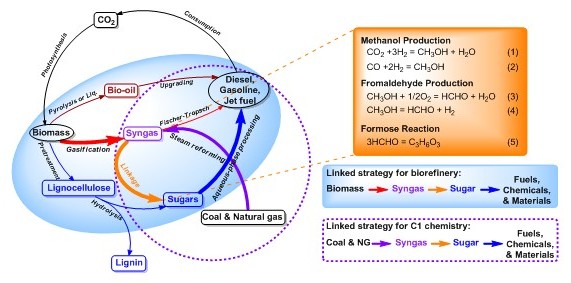

Based on the previous serial work that catalyzed and transformed biomass saccharides compound into liquid fuel(Angew. Chem. Int. Ed., 2009, 48, 652; ChemSusChem 2010, 3, 1172)and the research experience of the new catalyst(Energ. Environ. Sci., 2011, 4, 3552;Green Chem., 2012, 14, 2986),this seminar has raised the new strategy on the adoption of the formose reaction combined with biomass gasification and APP. The liquid fuel produced in this way will double the amount of that made by biomass gasification-FT while the energy retention rate is 1.2 folds than that. Also, it realizes the full component utilization of biomass, avoids the pretreatment of biomass in the traditional hydrolization featured by high energy consumption and high pollution and meanwhile explores a new path for C1 chemistry.

Fig 1:Strategy diagram of the adoption of the formose reaction combined with biomass gasification and APP/Courtesy of FU's group.

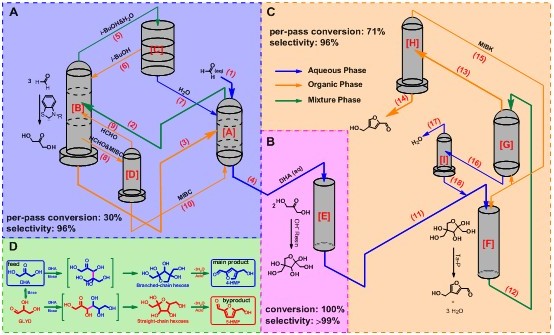

By functional regulation over catalyst, this team has achieved the selective control towards formose reaction, obtained the non-natural branched ketohexose with high productivity and high selectivity and paved the way for producing a new type of energy platform chemical-4-HMF. Via constantly optimizing the reaction condition and processing, this team has established a 4-HMF successive reaction apparatus, catalyzed and transformed the biomass-based formaldehyde into 4-HMF efficiently and meanwhile adopted the 4-HMF to synthesize branched alkanes fuel high in octane content and new oxygenated fuel-2, 4-dimethyl furan so that a brand new biomass-based liquid fuels production methods is developed depending on 4-hydroxymethylfurfural.

Fig 2: Process Flow Diagram of successively transforming formaldehyde into 4-hydroxymethylfurfural./ Courtesy of FU's group.

The research was sponsored by National 973 Program, Natural Science Foundation and Emerging and cross-disciplinary talents project of Chinese Academy of Sciences.

(ZHU Xiaocao, School of Chemical Sciences, News Center)

Back